The last time we checked-in, the NANORESTART team at Tate was working on analysing Op Structure by Michael Dillon and preparing mock-ups of the artwork to be used during cleaning tests by conservator Gates Sofer and researcher Dr Lora Angelova. The aim of the research was to find the best method for surface cleaning complex and difficult contemporary museum objects such as plastics and to explore scientific advances in nano- and gel-technologies for this purpose. During the summer, our understanding of how such novel cleaning systems would perform on our Op Structure mock-ups was as hazy as our knowledge of Michael Dillon. Over the last few months, we have carried out meticulous cleaning tests on the mock-ups, evaluated the results, and decided on conservation strategy for the sculpture. Unfortunately, our research into the artist has thus far hit a dead-end… it seems conservators and scientists can’t solve every mystery (yet!).

Left: Op Structure 1967 (T03717) by Michael Dillon

Right: the bottom of the sculpture, showing light surface soiling and a sticker that will be removed during the conservation treatment

© Michael Dillon

Photo © Tate

The plastic sculptures Dillon produced in the 1960s were made entirely of Perspex® sheets. The opaque, white sides of the boxes have a layer of light surface soiling and two types of stickers which we decided to remove during the treatment. To simulate these conservation challenges, we prepared Perspex® mock-up sheets coated with artificial finger grease (aka sebum), artificial soil, and two different types of stickers which matched the ones on the artwork. We artificially aged the stickered sheets to ensure the adhesive was fully dried and aged, and as difficult to remove as that on that actual artwork. While the mock-ups were ageing, we read about the best methods of cleaning plastic surfaces, chatted with our colleagues about how they would approach the problem, and consulted with our partners in Florence about the cleaning systems they are developing through the NANORESTART project which would be best for this case study. Based on the information we gathered, a list of more than 30 potential cleaning methods was created.

Left: Cleaning of the soiled mock-ups at in the Tate Britain Sculpture Conservation Studio. Each black-lidded jar contains a different type of cleaning liquid that was tested on the soiled sheets in the picture. Right: Some of the new gels developed in the NANORESTART project at CSGI, Florence, Italy being tested for the removal of stickers on our Op Structure mock-ups.

Photos © Tate

In October, we started evaluating the assembled cleaning methods. Whilst Gates carried out all of the cleaning tests (in triplicate!) Lora recorded observations on how each cleaning method performed in removing the soiling or the stickers, and whether the gloss of the plastic was altered. The ease with which the cleaning system could be obtained, prepared, handled, and applied was also rated, as were their health & safety characteristics. For example, a water-moistened microfiber cloth (a very soft cloth used by conservators which picks up a lot of soil and dust without being too rough on the surface) is very easy to obtain and use, and also very safe; however, it may not clean the surface as well as a microfiber cloth moistened with a soapy solution. And it is not much use for the removal of stickers with an aged, hardened adhesive. For removing stickers, an ideal method would be a gel cut to the same size and shape as the sticker, loaded with a specific liquid, and placed over the sticker until all of the adhesive is softened and the sticker can be removed in one piece without any rubbing.

At the end of the mock-up testing, we evaluated each test-site using a gloss meter, an infra-red spectrometer, and a colourimeter to gauge how the cleaning methods affected the gloss, surface chemistry, and colour of each test location, respectively. Because many of the cleaning methods performed very well when measured with these techniques, we also decided to take a closer look at the surface using a high resolution digital microscope. Under 1000-times magnification, we could see far better how well each cleaning method performed. For example, to the untrained eye, artificial soil was removed equally well from a mock-up by water, saliva, an equal-parts mixture of water and rubbing alcohol (2-propanol), Shellsol™ D40 (a mineral spirit), and a cleaning agent called triammonium citrate (TAC). However, our conservator’s evaluation (visualised through a ‘star diagram’ where each cleaning method is rated from 1 (lowest/worst) to 5 (highest/best) on a variety of characteristics) shows that mineral spirits reduced gloss (when applied with a cotton swab rather than a microfiber cloth), whilst the rubbing alcohol/water mixture was difficult to work with because it glided over the surface too easily, limiting the detailed and precise handling necessary during a conservation treatment. Furthermore, when we looked at each test area under the microscope, we found that many of the liquids had left small amounts of the soil on the surface; the mineral spirits had contributed to scratching of the surface by the dirt particles as they were being removed confirming the gloss changes that Gates had noted by eye.

Top left: A soiled mock-up before and after cleaning with some simple systems (water, saliva, rubbing alcohol/water, etc.).

Top right: A star diagram is used to visualise the performance of the cleaning methods according to the conservator; when a system performs well, it scores high values and its corresponding line covers the majority of the star-diagram area; a poorly-performing cleaning method scores lower and has less coverage of the star.

Bottom: Microscopy images of the mock-up pictured above under 1000x magnification (the scale bar at the bottom equates to 100 µm). Soil residues and some scratches are easily visible on the plastic at this level of magnification.

Photos and images © Tate

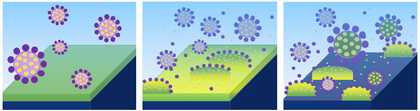

Not every cleaning system misbehaved on the microscale! When comparing results between Gates’s observations, our analytical techniques, and the microscope images, we found that some simple soapy solutions applied with a microfiber cloth removed the soil gently and effectively. We were also happy to find that some of the ‘microemulsions’ provided the perfect solution for removing the stickers. Microemulsions are liquids which contain suspended, nano-sized droplets of another type of liquid - much like salad dressing prepared from oil and vinegar can be shaken up to suspend small droplets of oil into the vinegar. Microemulsions function in a similar way but are very stable and do not separate like oil and vinegar mixtures. Using these complex liquids, we can deliver nano-sized droplets of a solvent good for softening the sticker glue without affecting the Perspex™ beneath because the main part of the liquid in the microemulsion is simply water.

Illustration of a microemulsion under magnification: The green surface represents the adhesive of the labels which can only be dissolved by the solvent contained inside the purple droplets. The purple droplets are suspended in water (indicated by light-blue in the picture), and can come into contact selectively with the adhesive. Once the adhesive is softened by the solvent in the droplets, it can be encapsulated and carried away inside the droplets. The Perspex beneath the sticker (navy blue) is primarily exposed to water rather than the solvent in the microemulsion droplets.

Illustration © Lora Angelova

Now that testing is complete, a strategy for the conservation of the two Op Structures in Tate’s collection can been designed. Look out for our last update from this series to see how Michael Dillon’s Op Art sculptures were cleaned.

Lora Angelova, Gates Sofer, Bronwyn Ormsby

January 2017